By Jack Shuttleworth, Director of Forma

A need to control costs while delivering demanding sustainability improvements is changing thinking about water attenuation.

The conventional approach, to install large tanks to hold water captured in gullies and slot drains, is proving, in many instances, to be no longer fit for purpose.

Climate change, causing more volatile weather, the subsequent need to reduce carbon emissions, a need to redevelop live and brownfield sites with complex ground conditions, and a strong imperative to control costs are stacked against tank systems that have held sway for decades.

Most optimised attenuation

It is why Manchester Airports Group (MAG), the UK’s largest airport group, selected a different approach to attenuation when it upgraded one of its main staff car parks.

Forma has been designed to streamline attenuation. It does it by keeping drainage shallow, creating a hugely flexible and scalable way to manage stormwater at source, without large tanks.

It is the most comprehensive and optimised subbase attenuation system on the market, and is simpler, quicker, less costly and safer to install.

Forma is also much more sustainable, with a carbon footprint a fraction of the size of traditional tank-based attenuation systems.

Forma ‘ticked all boxes’

MAG’s project perfectly demonstrates the advantage of shallow drainage. It needed to resurface and upgrade one of its largest park-and-ride staff car parks at Manchester Airport.

The project was designed by AECOM, the main contractor was Allied Infrastructure Management, part of Colas, and the attenuation installation contractor was SEL Environmental.

MAG had found the existing drainage and tank attenuation system was not holding water consistently.

Replacing it like-for-like would have represented a big proportion of the cost, time and risk associated with the project. So MAG was open to new ideas.

When we presented Forma, it recognised an ideal solution.

Daniel Wilmer, Capital Delivery Project Manager at MAG, said: “My brief was to come up with a solution. We’re all about innovation and sustainability and Forma ticked those boxes.

“I would like to use it across other sites. They’ve taken a lot of stress away and have been really reassuring in terms of what we require.”

Void space to hold water

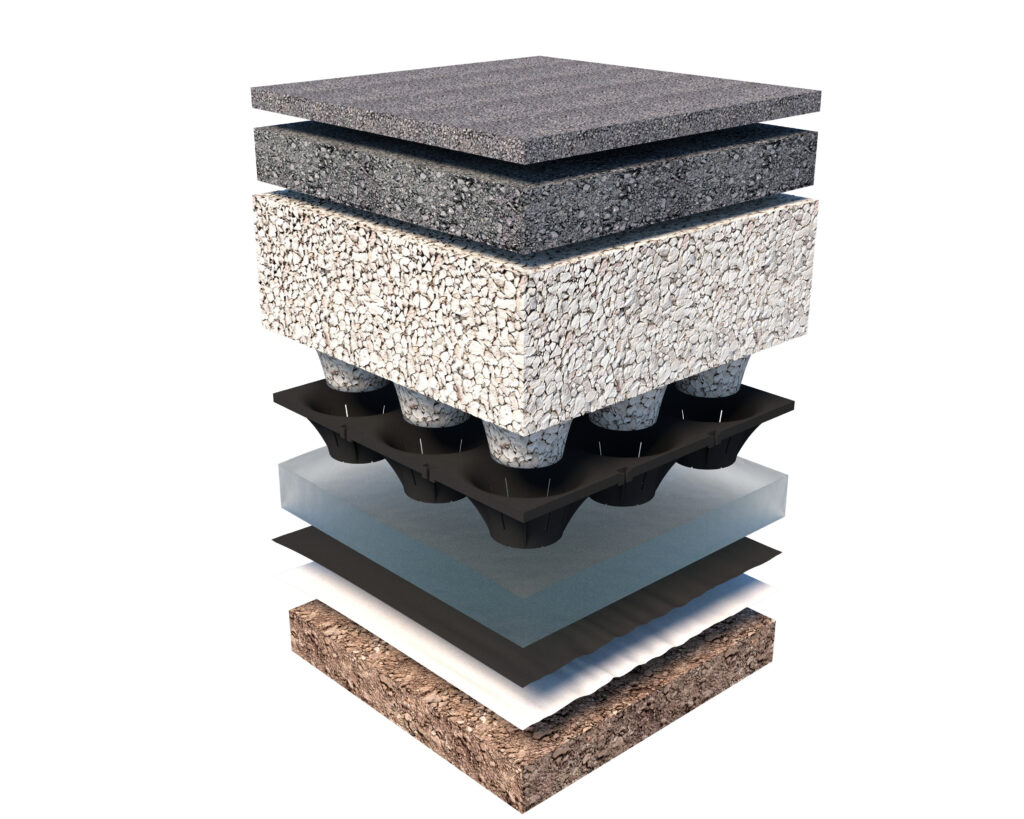

Central to the Forma solution for MAG’s car park is a product called Formavoid. It’s a modular system made from recycled plastic, here in the UK, designed with extremely strong columns and arches.

Quickly clipped together, fill material can be poured on top of the Formavoid raft, while 60% open ‘void’ space remains below for source control water storage and management.

The interlocked Formavoid modules – just 100mm deep – are positioned on top of a very strong, wedge-welded puncture-resistant geotextile membrane, called Formatextile.

The in situ car park surface and drainage system was removed with a 450mm-deep excavation. The Formavoid enhanced subbase attenuation system was installed across an area of 8,500m².

The system was designed to manage around 1,000 cubic metres of water. It was also more than capable of withstanding loads created by thousands of car movements and bus journeys every day.

Innovative water system

The Forma system was installed in five months by just six operatives in the second half of 2024.

Formavoid modules were integrated with 160mm-diameter plastic transport pipes. Just 100 metres of pipework were needed to collect water from across the carpark and take it to an outfall point.

A key innovation for this project was the use of checkdams within the subbase. This maximised the system’s attenuation volume across sloping ground.

The surfacing was completed with permeable asphalt in the parking areas and impermeable asphalt on the vehicle circulation route.

Right solution ‘critical’ – MAG

The Forma solution is already performing very well. It has exceeded expectations in terms of structural stability, achieving in excess of 80% CBR (a standard aggregate strength test) on top of the subbase.

This is very extremely impressive for a permeable open-graded subbase system, with much of the stability created by the Formavoid raft.

The system is design to attenuate a 1 in 100 year storm with an additional safety factor of 40% for future climate change.

Importantly, the Formavoid subbase is the ideal environment to intercept, contain and biodegrade hydrocarbons, as proven by many studies on pervious pavements.

So pollutants are removed from surface water before it is discharged into the stream, eliminating the need for expensive interceptor tanks.

Olivia Hughes, Senior Project Manager at MAG, pointed out: “Due to the staff car park being adjacent to a site of special scientific interest, it was critical that we did the right thing.

“The Forma system has been beneficial to MAG because it allowed us to only excavate to a shallow depth. It’s also a carbon zero product so we are reducing our emissions.”

Attenuation system of choice

The modular design of Forma will allow MAG to continue to implement the system in phases. For example, the rest of the car park could be upgraded in 2,000m² sections.

This aligns the solution with capital availability allows maximum flexibility to keep car parks operational. Forma is a progressive solution. Every square meter installed is a progressive improvement.

The project has also delivered many other advantages for MAG:

- The solution streamlined and simplified all elements of a large attenuation installation project.

- Much less material was excavated and moved, which saved significant costs.

- It also dramatically collapsed the project’s carbon footprint.

- Fewer truck movements meant less air pollution and improved road safety.

- The construction method was safer, as well, with no confined space entry.

- The project was completed much faster than a traditional tank-based solution.

In limited scenarios, installing large tanks will remain the only water attenuation option available.

However, shallow attenuation, as demonstrated by Formavoid at Manchester Airport, is ready for take-off. And will be the attenuation system of choice. For a lot of very good reasons.

Giving SuDS compliance a sporting chance

The Forma system is not just changing minds about water attenuation in the world of airport management or car park design.

It can be applied to many other water management challenges. For example, a Formavoid raft has been installed below the playing surface in a new stadium belonging to one of the UK’s most prestigious sports clubs.

Forma, based in Blackpool, Lancashire, is working with partners to widen its use to create the perfect drainage systems for the most high-profile sporting arenas across the world.

Storing water for reuse

Forma Director Jack Shuttleworth said: “The technology is ideal for controlling conditions needed to optimise grass growth and health, as well as installing modern hybrid playing surfaces that combine grass and other materials.

“Forma attenuation systems can also be combined with a wide range of permeable and non-permeable surfaces in public spaces, like school playgrounds and play areas, sports centres, parks, and city squares.”

What is more, the water can be stored and reused, for sports pitch, lawn, or plant bedding irrigation, or for use in public toilets.

Shallow attenuation represents an ideal response to Schedule 3 of the Flood and Water Management Act 2010.

This now requires developments to be authorised by local Sustainable Drainage System Approval Bodies (SABs) before they are granted planning permission.

The four main pillars of SuDS are:

- Quantity – the system must manage the expected volumes of water

- Quality – water must be fit to discharge

- Amenity – rainwater must, where possible, be usable

- Biodiversity – water should be used to support biodiversity

Jack Shuttleworth said: “Shallow attenuation adds a fifth pillar: true sustainability. It’s less costly, less disruptive, and is easier and safer to install, with a smaller carbon footprint than tank systems.”

Find out more

Forma has CPD programme to explain shallow attenuation to ground engineering and design consultancies, architects, and government planning teams.

Contact Forma: jack@forma.uk 01253 224375.

Recent Comments